Refrigerated Cargo – Cool Tips for Shippers

Before stowing your reefer container, make sure that:

- The cargo has been pre-cooled to the required temperature.

- The container’s external body and door gaskets are intact.

- The container is clean, odor-free, and in good condition, inside and out.

- The container’s floor and grooves are clean and unobstructed.

- All four drainage openings are clear.

- All relevant data (stowage date, temperature, vessel and voyage) has been accurately recorded on the chart and/or the ZIM sticker.

- The required temperature and air vent settings are clearly stated.

When stowing the container:

- Stow the cargo quickly and efficiently, keeping surface/pallet packing intact.

- Do not use a gas-powered forklift to stack surfaces/pallets, because its emissions can damage the cargo.

- Do not load any produce whose packing has been damaged during stowage.

- Check for and remove damaged fruit, because it can have a negative effect on the rest of the fruit in the container.

- The container should be opened as close as possible to the cold warehouse and the refrigeration unit should not be operated before or during stowing.

- Only activate the refrigeration unit after closing the container.

- Only the storage person (not a driver or anyone else) is authorized to lock the container with a security seal. The container seal number should be clear and legible, and must remain covered.

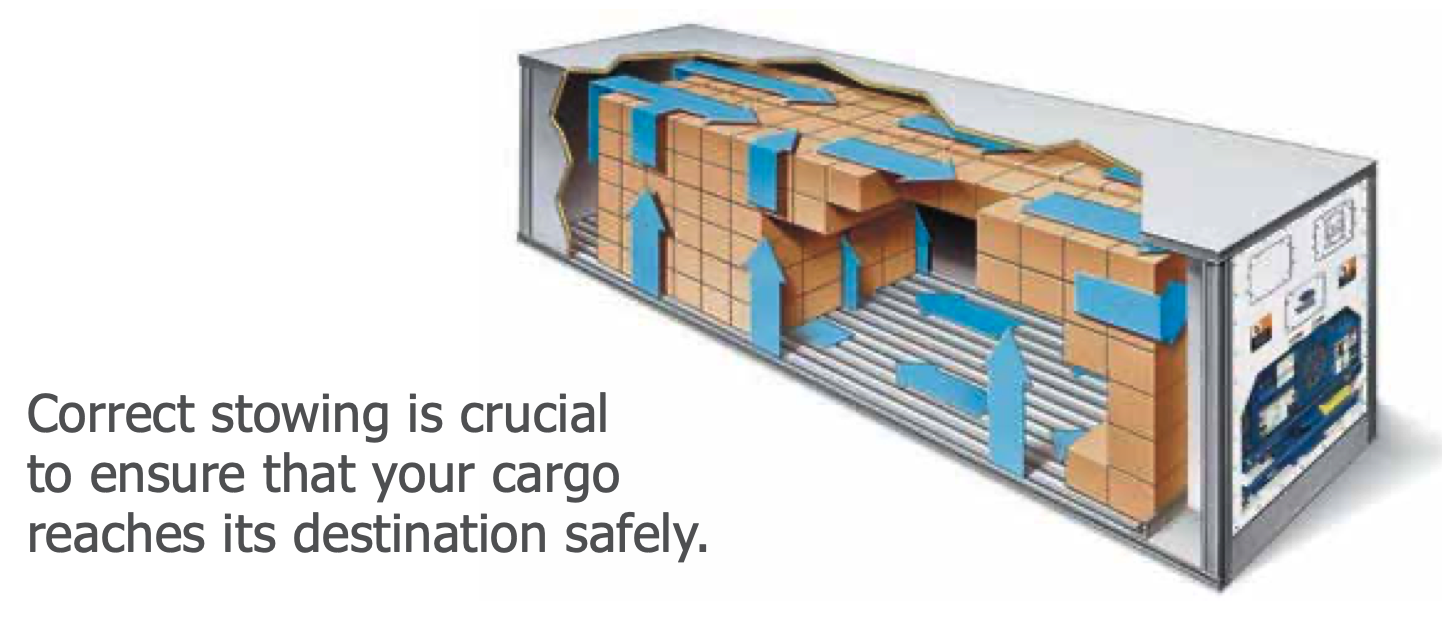

To ensure uninterrupted airflow:

- Do not leave excess space between cargo.

- Do not leave excess space in front of the door.

- Do not leave excess space in front of the machinery.

- Leave enough space between the cargo and the doors to allow free air circulation.

- Do not stow goods above the red line.

- Double check that all air vents have been set to meet your requirements.

Before moving the container to the port or terminal, ensure that:

- The driver has been instructed to check that the container is operating correctly throughout the land transportation leg, and to report any changes immediately in order to receive instructions.

When delivering the container at the port or terminal, the driver should ensure that:

- The container is in good working order throughout the waiting period at the entrance to the port/terminal.

- After discharge at the port/terminal, the container is immediately connected to a power source.