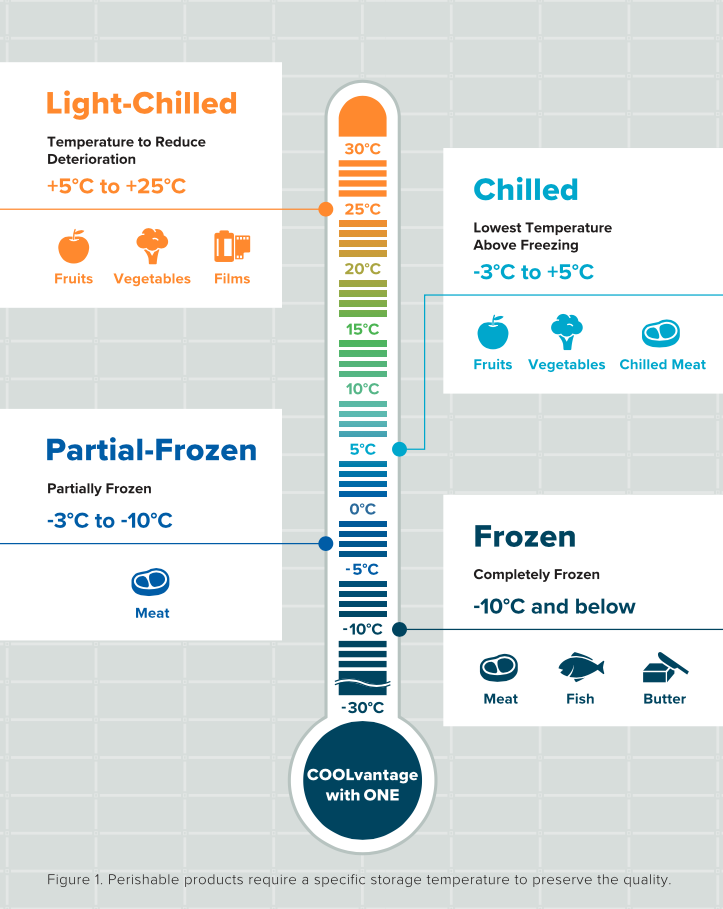

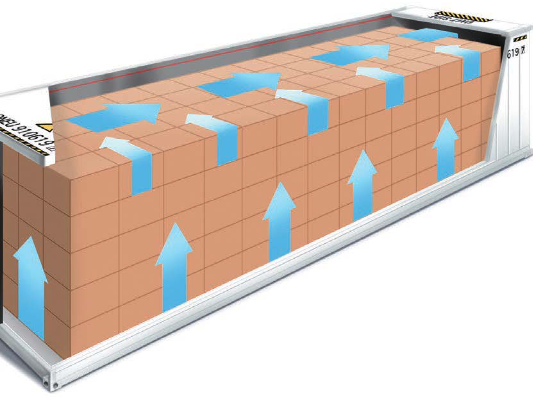

The refrigerated cargo industry relies very heavily on consistency. From predictable delivery schedules to temperatures being maintained at a predetermined constant throughout the cargo’s journey, cold chain solutions must cater to the growing needs of the industry around the world.

We believe the ideal refrigerated shipping solution will give customers end-to-end visibility and transparency of their cold cargo and so much more than simple storage and transportation.

Your refrigerated quote and load will be handled quickly, and you will also receive excellent customer service. Add to that the fact that we are available 24/7 and you have a fantastic new partner.